|

Products

PTP aluminum

foil

or

Blister Foil

Alu Alu Foil

or

Cold Forming Foil

Strip

Foil

Suppository Packing

Laminated Film

Aluminum Foil

Paper

Tropical

Blister Foils |

Cold Forming Foil

Cold forming foil is also called cold formed blister

foil, this foil consists of nylon, Alu, and PVC, and

Cold forming foil is cold stamping, such require that

manufacturer shall have high accuracy stamping equipment

to ensure quality of Cold forming Foil and avoid raw material

waste, moreover, high quality cold forming foil can ensure

that tablets can be packed safely, and tensile property

of Cold forming Foil shall be strong enough to be not easily

torn. Mould to be stamping cold forming Foil can be verified

so that diverse shape of cold forming foil can be offered.

In cold forming foil cold forming

progress, an aluminum-based laminate film is simply pressed into a

mold by means of a stamp. The aluminum foil will be elongated and

maintain the formed shape. These blisters are called cold form foil

blisters. The principal advantage of cold form foil blisters is that

the use of aluminum offers a near complete barrier for water and

oxygen, allowing an extended product expiry date. Compared to

thermoforming, cold form foil blisters is slower in speed of

production.

General Description

Cold forming foil is offered for heat sealing

with blister foil. Cold Forming Foil offers an excellent multilayer

in configuration for high sensitive range of pharmaceutical and

generic medicines that are highly hygroscopic or light sensitive

but not suitably packed with barrier plastic films.

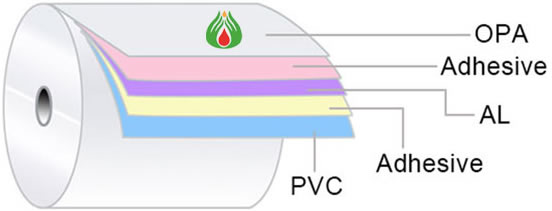

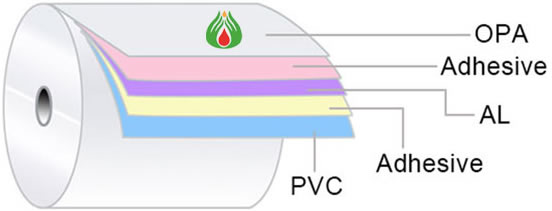

Configuration

of Cold Forming Foil is usually OPA (Nylon) film 25μ / Adhesive /

Aluminum Foil 45-60μ / Adhesive / PVC 60μ.

Other specifications in configuration of Cold Forming Foil can be

available to meet customers’ requirement.

Characters:

? Full barrier against water vapor, gases, light;

? Excellent Thermo-formability

? High degree of Thermal stability

? High Malleability for deep drawing blister cavities

? Sealable with normal aluminum Foil

? Effective anti-counterfeit packaging

|

Cold Forming Foil offered by Hanlin Company

Cold Forming Foil

Configuration

|

Technical Data of Cold Forming Foil:

Test Parameters |

Units |

Specification Value |

Tolerance Limit |

Final Value |

Total Grammage |

GSM |

248 |

+/- 8% |

228-267 |

Total Thickness |

Micron |

145 |

+/- 8% |

133 - 157 |

Opa Film |

Micron |

25 (29 GSM) |

+/- 8% |

26-31 |

Adhesive |

GSM |

5 |

+/- 1 GSM |

4 – 6 |

Aluminium Foil |

Micron |

45 ( 127 GSM) |

+/- 8% |

116 - 137 |

Adhesive |

GSM |

5 |

+/- 1 GSM |

4 – 6 |

PVC Film |

Micron |

60 (84 GSM) |

+/- 8% |

77 - 91 |

Width MM |

- |

- |

+/-1 MM Within Specs Limit |

|

Bond Strength |

GSM / 15MM |

450 |

Min Value |

On plus side |

Seal Strength |

GSM / 15MM |

500 |

Min Value |

On plus side |

WVTR |

G/ M2 / 24HRS 38°C |

98% RH 1 |

Max Value |

NIL |

When customer asks inquiry

for cold forming foil, he has to offer us width of cold forming

foil,

and whether the cold forming foil shall be printed or not. We are willing

to offer customers cold forming foil sample without charge for his test,

if customers test machine is bought from China, we are willing to

send the asked sample to the test machine manufacture.

Application of

Cold Forming Foil

|