|

Products

PTP aluminum

foil

Alu Alu Foil

Tropical

Blister Foils

AL/PE Strip

Foil

Composite film

Paper Aluminum Foil

Suppository Packing |

PTP blister foil

“PTP” in PTP blister foil is

abbreviated from “Press through Packing”, in Europe, “PTP” is known

as “Press through Foil”, in China, PTP blister foil is named

“Pharmaceutical PTP blister foil”, PTP blister foil that is also

known as blister foil or push-through lidding foil is offered for

heat sealing with PVC, PVDC-coated PVC, PP for pharmaceutical

purpose in blister packing process, such as capsules, tablets, pill,

and etc. PTP blister foil features oxygen resistance, moisture

proof, leak proof, pollution proof, light proof, light weight, high

tension strength and low shrink, and PTP blister foil can be easily

cut in automatic production line, moreover, being easy pressed

through of PTP blister foil distinctive character compare to other

packing material ensures drugs can be drawn out easily.

PTP blister foil can be unprinted foil and printed foil, and

printed foil can be printed on one side or both sides, weight of PTP

blister foil varies due to unprinted or different printed.

PTP blister foil

is offered for pharmaceutical

purpose in blister packing process, such as capsules, tablets, pill,

lozenges

and etc. PTP blister foil features oxygen resistance, moisture proof, leak proof, pollution proof, light proof, light weight, high tension strength and low shrink,

and a degree of tamper resistance, and PTP blister foil can be easily cut in automatic production line, moreover, being easy pressed through of PTP blister foil distinctive character compare to other packing material ensures drugs can be drawn out easily.

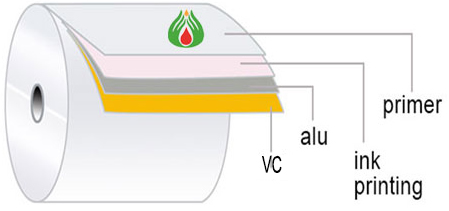

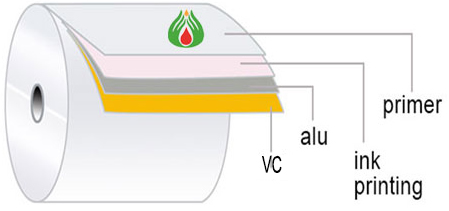

Basic configuration of PTP blister foil is Protect layer (OP)/Outer printing layer/Aluminum foil based-material (AL) inside printing layer/Bond (VC).

|

Detailed Description |

PTP blister foil product |

|

Advantages and characteristics of Hanlin PTP blister foil are as follows:

Raw materials are offered by qualified suppliers, such assure quality of

blister foils;

Hard anodized aluminum is applied as cover material of PTP blister foils to ensure these aluminum foils can be easily to be broken for drugs;

Oxygen resistance, moisture proof, leak proof, pollution proof, light proof and etc. of characters of PTP blister foils to protect effectively medicine being packed;

Super mechanical properties with anti-corrosion of PTP blister foils ensure these PTP blister foils can be applied in high speed pharmaceutical packing production line at low or high temperature applicable;

No-peeling heat-sealing coating of PTP blister foils ensures to be heat sealed excellently with plastic-based materials such as PVC, PVDC/PVC, PP and etc.;

Printing of PTP blister foils can be available in plain foil(no printing), printing foil (one-sided printing, two-sided printing, single-color print, double color printing, polychrome printing), color foil (one-sided golden color, two-sided golden color, green bottom color, each kind of colored bottom color), forgery-proof (stealth writing, design, positive and negative printing), while single side or double sides printing assure better appearance upon request;

Perfect printing ensures no fading after being sealed;

Specification of PTP blister foils are often as follows: OP/AL 20-40μ(H)/VC and OP/AL 20-40μ(O)/VC

PTP blister foils are often offered as follows:

Standard Foil Gauge Options |

Tolerance (+/-8%) |

0.020 mm |

+/- 0.0016mm |

0.025 mm |

+/- 0.002 mm |

0.030 mm |

+/- 0.0024 mm |

Different specifications of PTP blister

foils for special purpose may be available, and feel free to contact us for your

purpose. |

|

|

Technical

data of PTP blister foils are offered as follows:

Winding direction : |

Generally printed or clear lacquer side is out with

heat Seal coating inside. |

Core: |

Material options: (a) Plastic (b) Aluminum (c) Card

Board

Core ID: 76 mm +/- 0.5 mm

The length of the core is equal to the width of the

web. |

Splices: |

Butt type made with 25 mm pressure sensitive tape. |

Reel outer diameter : |

250 +/- 10 mm for slit material, 400 +/- 10 mm for

Jumbos |

Reel wander: |

Within +/- 1 mm |

Reel/web width: |

Plain: 60mm to 800 mm with a tolerance of +/- 0.5

mm.

Printed: 60mm to 600 mm with a tolerance of +/- 0.5

mm |

Joints per reel: |

Maximum 2. Average less than 1. |

Pin holes: |

0.025 and 0.03 mm foils are free from pin holes.

In 0.02 mm foil, 40% of foil is free from pin holes,

rest less than 10 PSM |

Identification: |

Each reel shall be identified with a sticker pasted

inside the core with Reel numbers. Specification,

Net weight, Operator number & Date manufacture. |

Packing: |

PTP blister foils are packed in cardboard carton.

Relevant markings are provided on each outer

package. |

Recommended operating

conditions: |

Sealing temperature :170 to 180 deg. C

Sealing pressure : 2.8 to 5.6 kg/Sq. cm, 40 to 80

lbs/Sq. inch

Dwell time : 0.25 to 0.5 sec. |

Covering area of

1 kg finished material (nominal) : |

Gauge & Temper Foil

0.02 (hard)

0.025 (hard)

0.03 (hard) |

Covering area in Sq. M/Kg with 4 GSM nominal Heat

Sealing Coating

17.18

13.94

11.72 |

Table showing thickness tolerances of foil: |

Foil Gauge |

Thickness ( mm ) |

GSM |

Min.

(-8%) |

Nominal |

Max.

(+8%) |

Min.

(-8%) |

Nominal |

Max.

(+8%) |

0.020 mm |

0.018 |

0.020 |

0.022 |

49.9 |

54.2 |

58.5 |

0.025 mm |

0.023 |

0.025 |

0.027 |

62.33 |

67.75 |

73.17 |

0.030 mm |

0.028 |

0.030 |

0.032 |

74.80 |

81.30 |

87.80 |

|

Test certificates: |

Test certificates giving the actual observed values

of different parameters will accompany the supplies. |

|

PTP blister foil configuration

Coating Thickness Options:

(a) 4-6

GSM with a tolerance of +/- 0.5 GSM

(b) 6-8

GSM with a tolerance of +/- 0.5 GSM Standard, if not specified,

heat sealing coating GSM is 4 with a tolerance of +/- 0.5.

Seal

Strength with PVC/PVDC:

8 N/25 mm min.

Printing and Lacquer Coating:

Printed

as per text, layout and shade approved by customer. For

non-printed specification, clear lacquer to be coated as a

protective coating and good printability. Printing inks and

lacquer coatings are capable to withstand 180 deg. C for 1 sec.

dwell time.

Configuration:

Printed

and Unprinted PTP blister foils are available in the reel

forms. Unprinted blister foils are also available as Jumbo roll.

|

General Information:

Quality of PTP blister foil

are often subjected to different raw materials, statement of

the same raw materials, rolling progress of blister foil,

thickness and thickness clearance of blister foil, pinhole

scattered in aluminum foil, and surface conditions of

aluminum foil.

Raw aluminums for PTP blister

foil can be hard aluminum (often called “H18”) or soft

aluminum (often called “0”), hard aluminum are those not

being softened aluminum foil after rolling (aluminum foil

are not annealed after rolling), while soft aluminum are

those being softened aluminum foil after rolling (aluminum

foil are annealed enough after rolling).

Raw aluminums for PTP blister

foil are often alloy aluminum 1100, 1145, and 8011. Tension

strength, ductile, anti-fracture strength of PTP blister

foil made from 8011 is better, and seldom be broken when

being heat-sealed with PVC.

Mechanical properties of two

statements for the three raw alloy aluminum foil samples are as

follows, thickness of the three samples is 0.020mm:

Alloy |

1100 |

1145 |

8011 |

Tension strength

N/mm² |

Ductile

% |

Fracture strength

kpa |

Tension strength

N/mm² |

Ductile

% |

Fracture strength

kpa |

Tension strength

N/mm² |

Ductile

% |

Fracture strength

kpa |

H18 |

≥140 |

1 |

≥160 |

≥135 |

1 |

≥130 |

≥160 |

1 |

≥180 |

0 |

40-105 |

1 |

— |

40-100 |

1 |

70-90 |

50-105 |

1 |

130-160 |

Anti-fracture strength of two

statements for four thicknesses of PTP blister foil

thickness

statement |

0.016mm |

0.020mm |

0.026mm |

0.030mm |

H18 |

— |

130-140kpa |

160-190kpa |

170-270kpa |

0 |

50-60kpa |

70-90kpa |

100-110kpa |

130-140kpa |

Heat-seal strength of two

statements for four thicknesses of PTP blister foil (sealed

with PVC at 150℃ 0.02Mpa 1S; peeled at 180°, speed: 200mm/min)

Thickness (mm) |

0.016(0) |

0.020(H18) |

0.030(0) |

0.030(H18) |

Heat-seal strength |

4.9-7.0N/15mm |

8.3-11.0N/15mm |

7.3-10N/15mm |

13.2-16N/15mm |

Fracture strength of two statements for three thicknesses of

PTP blister foil (sealed with paper/AL/VC)

thickness

statement |

0.016mm |

0.020mm |

0.030mm |

H18 |

— |

310-360kpa |

— |

0 |

210-260kpa |

— |

240-300kpa |

Thickness of PTP blister foil

is usually 0.020mm. GB 3198-2003 aluminum and alloy

aluminum foil specifies that thickness of raw aluminum

should be 0.020±8%mm,

most manufacturers control thickness clearance of raw

aluminum foil within 5%, that is thickness of

aluminum foil is 0.020±0.001mm.

YBB00152002

specifies that coating

thickness clearance should be

within ±10.0%,

that is thickness of aluminum foil with coating is 0.024±0.003mm.

When

customer asks inquiry for PTP blister foil, he has to offer us

width of PTP blister foil, and whether the PTP blister foil shall

be printed or not. We are willing to offer customers PTP aluminum

foil sample without charge for his test, if customers test machine

is bought from China, we are willing to send the asked sample to the

test machine manufacture.

PTP

aluminum foil is offered in rolls, and these rolls are packed in

cardboard boxes. Many PTP blister foil blister packaging machines

use heat and pressure via a die to form the cavity or pocket from a

roll or sheet of plastic. In recent years, improvements in cold

forming, specifically allowing steeper depth/angles during forming,

which minimizes the amount of material used for each cavity—have

helped this technology increase. The main advantages of the

plastic-based blister pack are its more compact size compared to

cold formed aluminum and its transparency to see the product.

Application of PTP blister foil

When customer asks inquiry

for PTP blister foil, he has to offer us width of PTP blister

foil, and whether the PTP blister foil shall be printed or not. We

are willing to offer customers PTP blister foil sample without

charge for his test, if customers test machine is bought from China,

we are willing to send the asked sample to the test machine

manufacture. |